Capstone team delivers trike improvements

When is a trike, more than a trike?

When young engineers imagine ways to improve it — and then build a prototype to test it out.

Youth en Route (YER) is pleased to share improved adaptations for trikes that will enable more special needs students to experience the joy, skill-building, social and physical development that comes with riding a bike at school.

A team of six graduating mechanical engineering students took on the project to improve the trike as part of their Capstone design class, working alongside YER adaptive cycling instructors, mechanics and fabricators.

Team problem solving

The team, Alexandra Veckenstedt, Maria Saravia, Marcus Zamzow, Tomas Beltran, Yifan Yu and Derek Zamzow, was tasked with adapting a Kross Trike (purchased from B&P Cycle) to improve safety and the variety of youth that can use it.

The new trike has four main innovations that solve problems YER deals with every day as we work with commercially available trikes.

Problem: Kids who are new to cycling often don’t know the correct pedalling motion. A fixed gear bike, where the pedals move with the wheels, helps them learn to pedal. But as kids gain skills, they are safer with a coasting drivetrain where they can stop pedalling and the bike rolls. Currently YER has a fixed gear bike that it brings to schools for learning.

Innovating solutions

Solution: Fixed-Free Drivetrain where the trike can move easily between gear modes. Using simple, durable design using only two custom parts. Derek Zamzow and Beltran went through a few iterations before landing on the final design that works by engaging two pins.

Problem: Capable riders can get going too quickly for the confines of a gym. The only way to slow them, is to put the bike in a higher gear, making it more difficult to pedal. But that means the bike travels further, increasing speed, instead of decreasing it

Solution: Remote slowing and braking mechanism that can be engaged by a teacher on a computer. Engaging the brakes to a level of 20 or 30% means students must work a bit harder to pedal and move the bike. The remote tool can also stop the bike safely. Marcus Zamzow developed a simple computer program and worked with Yu on motor system to engage the brake. The mechanism sits in the bikes rear basket. It allows external supports to stop or slow riders to avoid dangerous situations.

Variety of kids no longer requires multiple bikes

Problem: Many different sizes and abilities of students. It’s difficult to provide bikes for all students. For example, some students with less function on one side, struggle to engage a hand brake if it’s on the wrong side. Similarly – some students need their feet attached to the pedals to be successful, other students react negatively if their feet are strapped in.

Solution: Veckenestedt and Saravia designed broad handlebar with many potential hand placements and a hand-brake that can easily be switched to a better location for the rider. The seat, with a backrest, is a more supportive option and the pedal platforms, which are 3D printed, snap on and off the existing pedal like a ski binding. They come in three sizes with Velcro to hold the foot securely.

YER’s Adaptive Cycling Program delivers trikes to schools and supports teachers and students to learn to ride safely, usually in gyms. School year to date, the program has reached 217 students at 13 schools with more planned in the spring.

Ready to test

Once the engineering team completes their course requirements, the improved trike will be taken to a school for testing with students.

“We are really excited to see these improvements in action. Currently, the trikes on the market work, but only for a few students for our programs. Our hope is we can move to manufacturing the adaptations on a larger scale to get more kids riding,” said Laura Shutiak, who was the team’s industry advisor on the project.

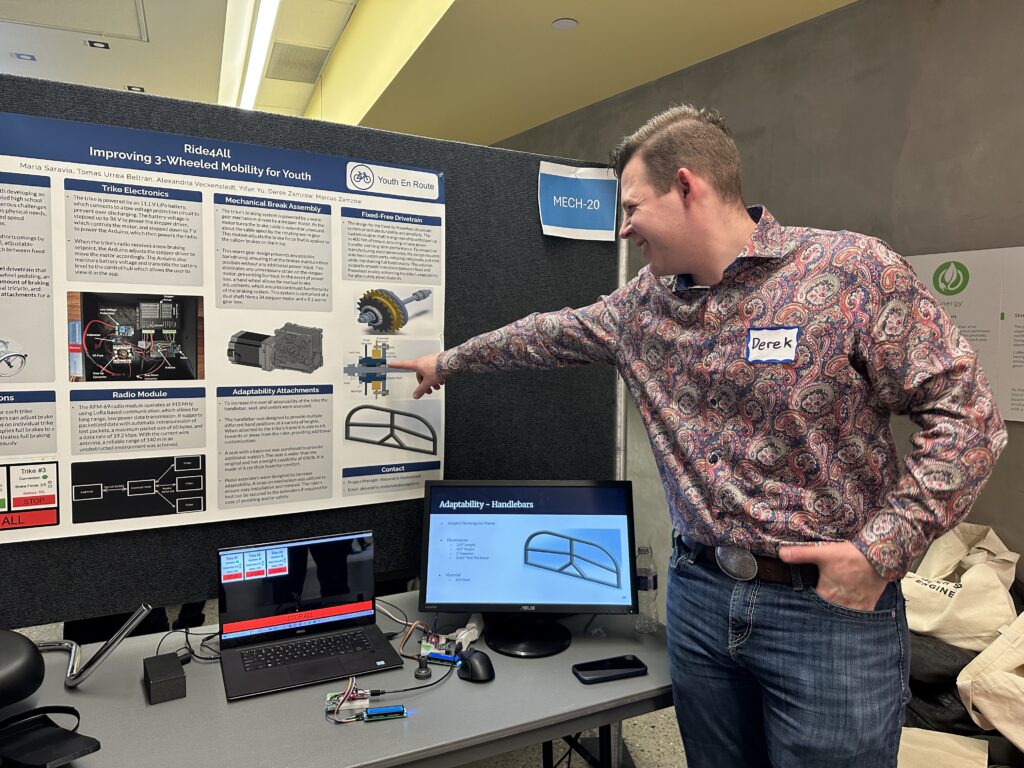

At the recent Capstone Design Fair at the U of C, the team was busy answering questions from interested visitors, media and judges.

“I think the beauty of this project is that its plain to see the impact it will have in the community,” said Veckenstedt. “We’ve been fortunate to be able to work on a project with real-life applications that will support bikes for all.”